Historically, on forging rolls, the transfer of parts between the different forging stages was carried out manually by an operator, then on automatic forging rolls, the transfer began to be carried out using manipulators and robots.

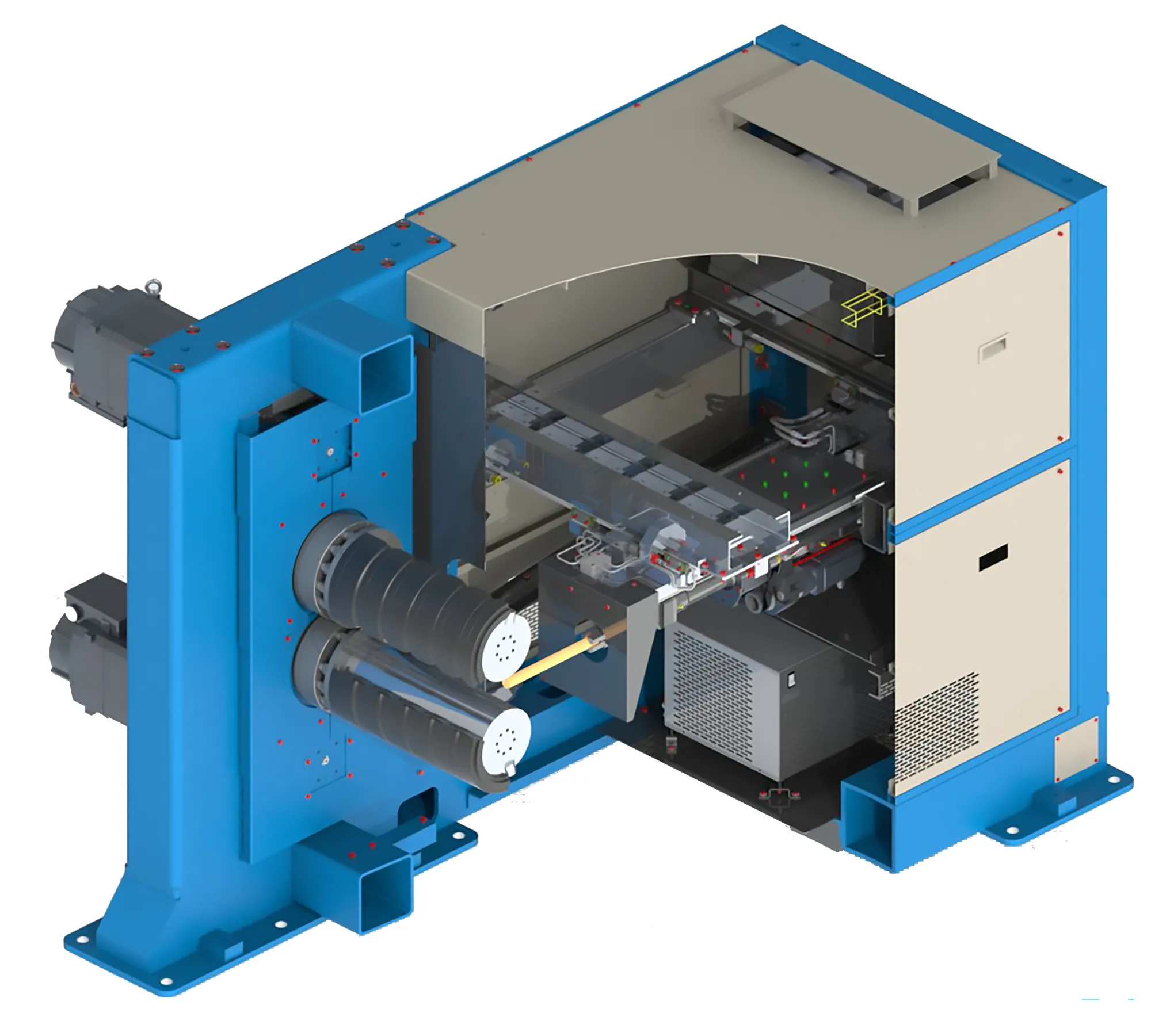

In 2020, ECAI completely redesigned this type of automatic strip rolling mill, integrating a 2-axis magnetic field manipulator.

ECAI is constantly evolving its design to ensure that its products remain innovative.

The principle of theautomatic forging roll is to roll a round or square piece of steel, alloys, aluminium, titanium, etc. in order to move the material along the longitudinal axis to obtain a preformed billet, which saves money during press forging.

This rolling action is performed by moving the piece back and forth successively between the rolling sections mounted on two motorised rollers. During these successive passes, the billet is positioned and synchronised with the rollers using a manipulator.

The undeniable advantage of ECAI forging rolls is that they have a 2-axis manipulator with magnetic fields.

Magnetic fields are used to position and synchronise the speed of the manipulator without any mechanical connection, which avoids tedious adjustment operations.

The magnetic fields are used to position and synchronise the speed of the manipulator without any mechanical connection, which avoids the need for time-consuming adjustment operations. In addition, the rotation of the tongs is provided by a servomotor, which allows them to be positioned at any angle within 360°.

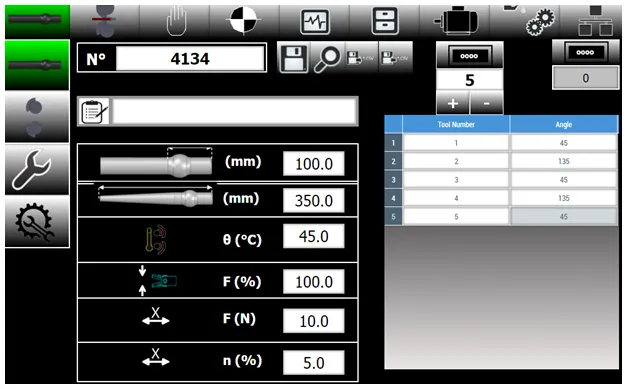

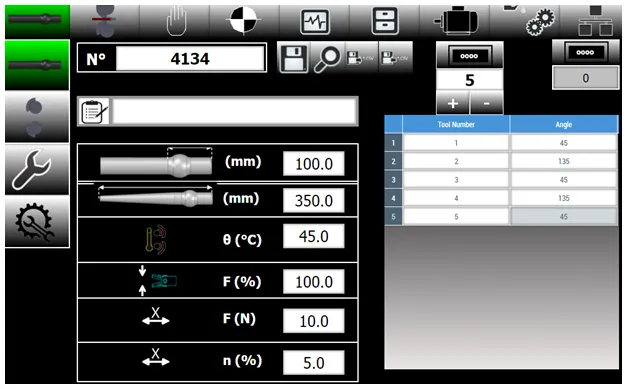

Thanks to its intuitive control system, the forging cylinder and manipulator settings can be adjusted from the control panel.

The system records all the data needed to better control the rolling process: speeds, torques, forces, etc.

This allows rapid changes in production, thanks to the rolling recipes stored in the control system.