Founded in 1994 and initially specialised in process engineering and industrial electricity, ECAI carried out its first retrofit of a radial-axial ring rolling mill a few years later, quickly becoming one of the leading players in the field of machine modernisation.

ECAI always listens to its customers' needs in order to understand their problems and provide them with the best technical solutions.

Thanks to its mechanical design department, which develops its new machines, ECAI has all the necessary experience to size, design and modernise ring rolling mill components.

ECAI can provide its own solutions for hydraulic modernisation, relying on its long-standing partner to implement them.

Thanks to its extensive network of qualified European suppliers, both for mechanical and hydraulic components, ECAI is able to help its customers find spare parts and specific components.

Thanks to its extensive experience in the field of electrical and industrial processes, ECAI can provide its customers with fully customised solutions for complete or partial upgrades of hydraulic machines.

As a SIEMENS partner in the field of automation and drives, ECAI can offer innovative developments in the areas of process and motion control.

ECAI has developed its own machine control software, RingLab®, based on a Beckhoff system as a completely open system.

RingLab® allows higher-level communication via CSV (Excel) files or its open SQL database.

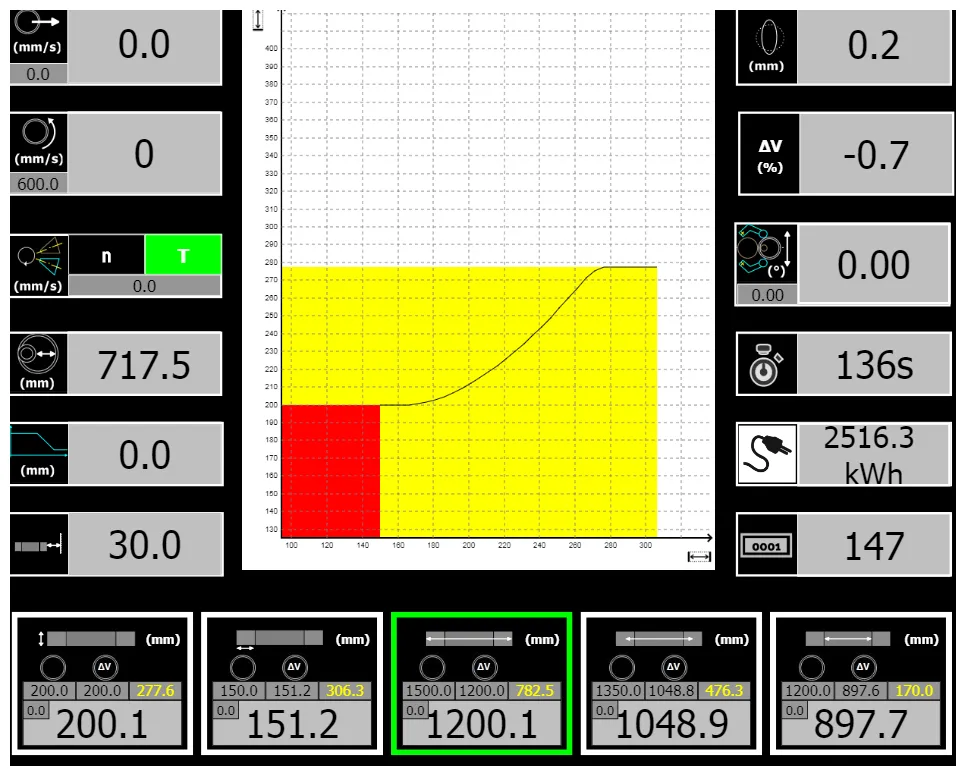

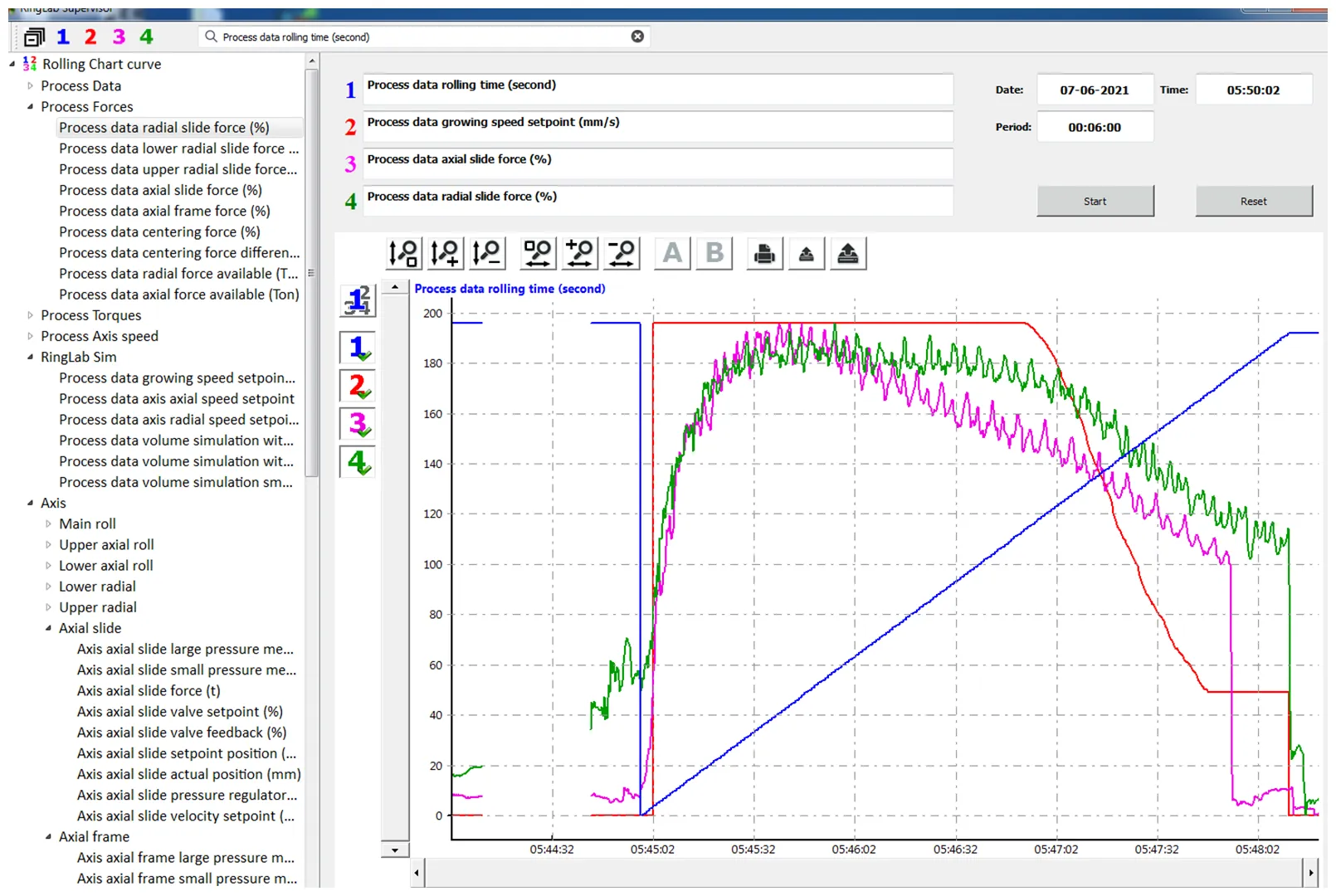

Thanks to RingLab® Supervisor, it is possible to monitor the recording of all running data (more than 400 parameters). This can be done directly on the machine or on a computer connected to the machine.

The RingLab® software enables powerful and efficient remote support worldwide.