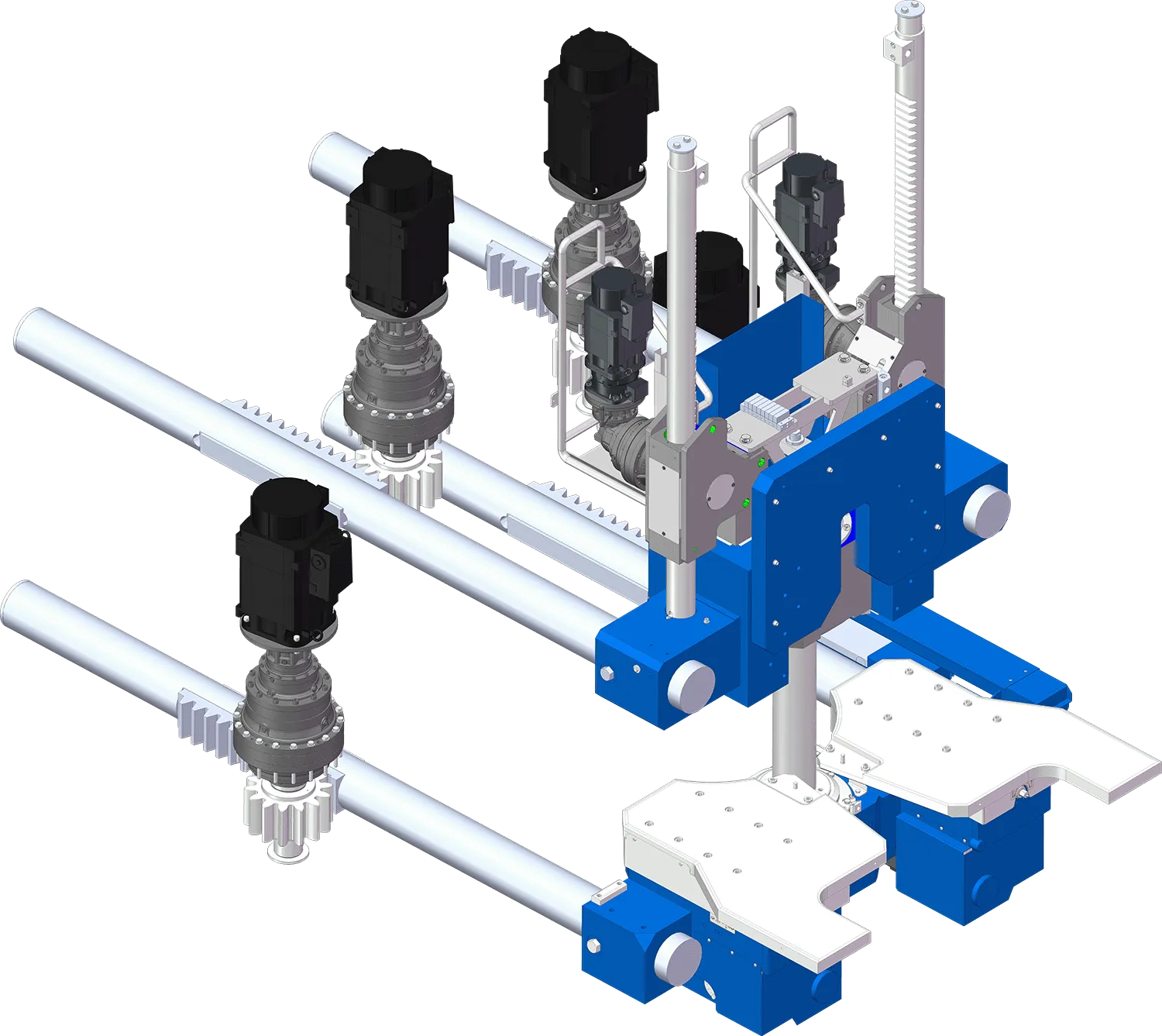

Building on its experience, in 2005 ECAI developed a new concept for radial-axial ring rolling mills, replacing the hydraulic cylinders with rack and pinion assemblies driven by servomotors. This innovative approach, now widely proven by a substantial number of machines in service, marked a decisive step forward in the field of ring rolling.

ECAI is constantly improving its design in order to always guarantee an innovating product.

Our range of machines is suitable for the production of rings, discs and profiles. The radial and axial cages and centring arms are driven by electromechanical drives, unlike traditional ring rolling mills which use hydraulic cylinders. This technology offers several advantages, including:

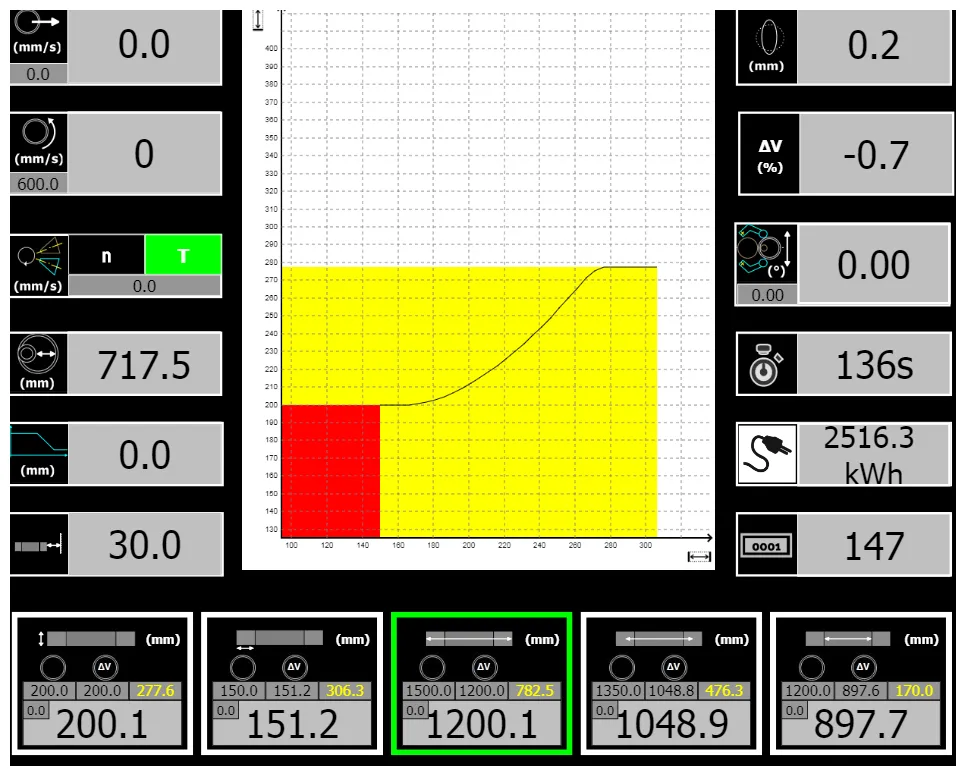

Our RingLab® control system is highly intuitive and uses graphical symbols rather than text.

In most cases, only the dimensions of the blank and the final part need to be entered by the operator, with the system automatically calculating all the relevant parameters.

RingLab® is completely open to the outside world via CSV (Excel) files or its open SQL database, allowing for exchanges with a higher level.

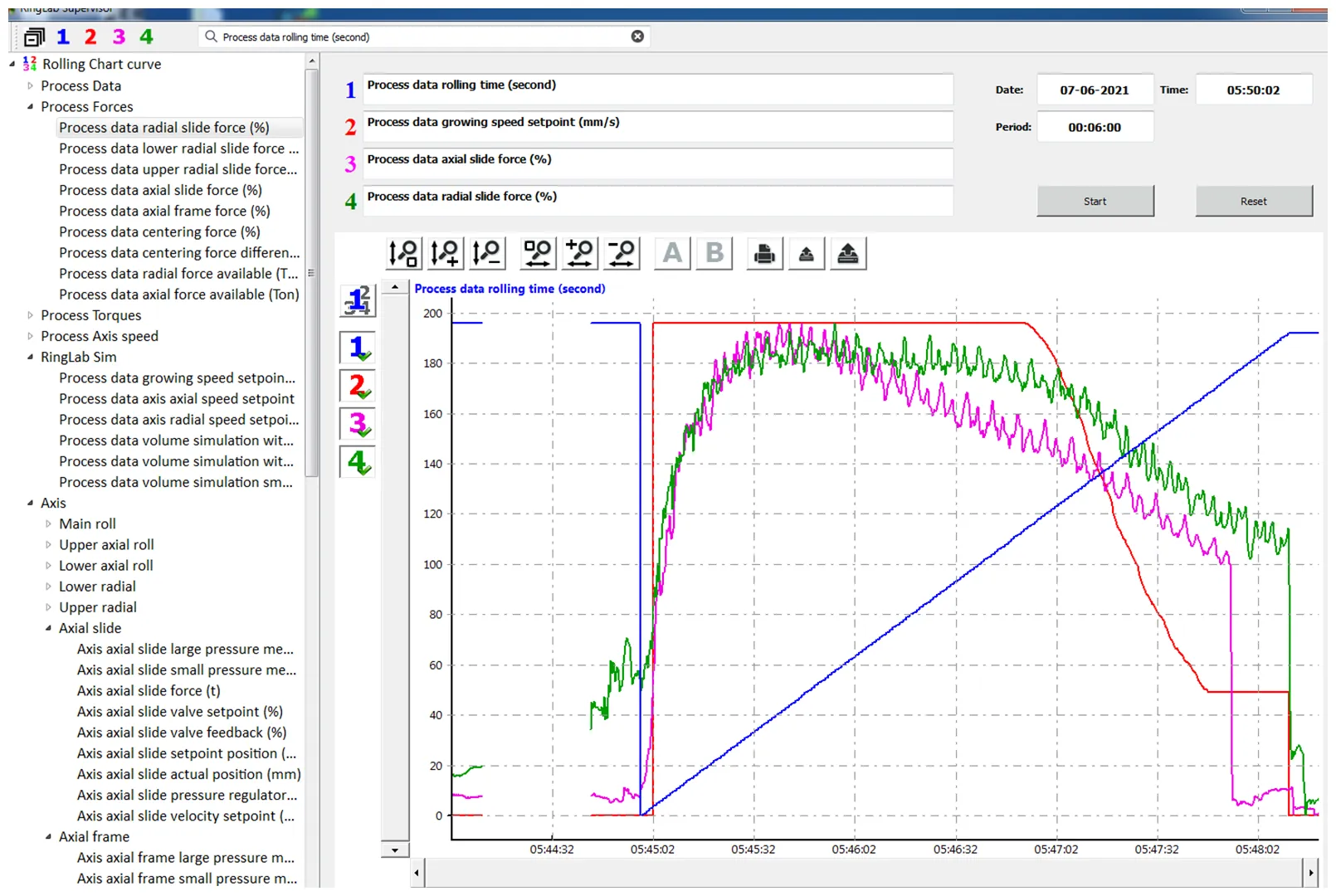

Thanks to RingLab® Supervisor, it is possible to monitor the recording of all rolling data (more than 400 parameters).

This can be done directly on the machine or on a computer connected to the machine.