Multi-mandrel ring rolling mills were developed in the 1950s and more than 200 of them have been produced. In 2013, ECAI® completely redesigned this type of rolling mill, notably by integrating servo motors.

ECAI® is constantly improving its design to ensure an innovative product.

With a production capacity of up to 720 pieces per hour, this machine can produce rings with a diameter of up to 350 mm in large series. By using profiled mandrels and/or main rolls, it is possible to obtain crowns with internal and/or external profiles. It can be used individually or integrated into a fully automated line.

Combined with a calibration press, it provides a high-precision product.

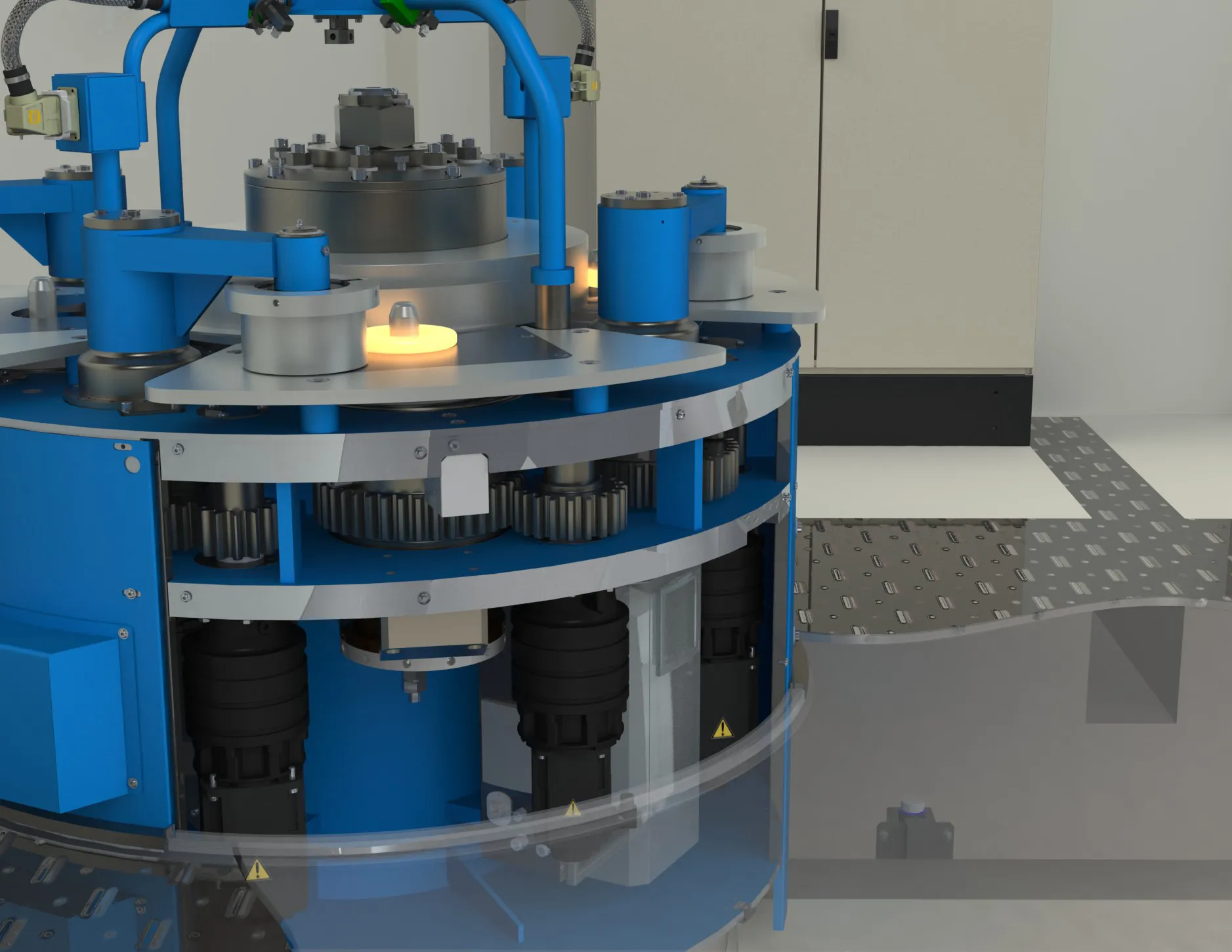

This machine is equipped with 4 mandrels and a main roll. The mandrels are positioned on a table that rotates eccentrically around the main roll. In this way, each mandrel moves from a remote position to a position close to the main roll, bringing the blank from the loading area to the rolling area and then to the unloading area.

Thanks to its intuitive control system, the rolling mill settings: wall thickness of the ring, centring arm holding force, rolling capacity, rolling speed and, optionally, mandrel height positioning, can be adjusted automatically.

This allows for quick production changes, thanks to the rolling recipes stored in the control system.